Flat Dilatometer Test (DMT) was firstly developed in Italy by Professor Marchetti in the mid-70s and currently used in more than 40 countries around the world.

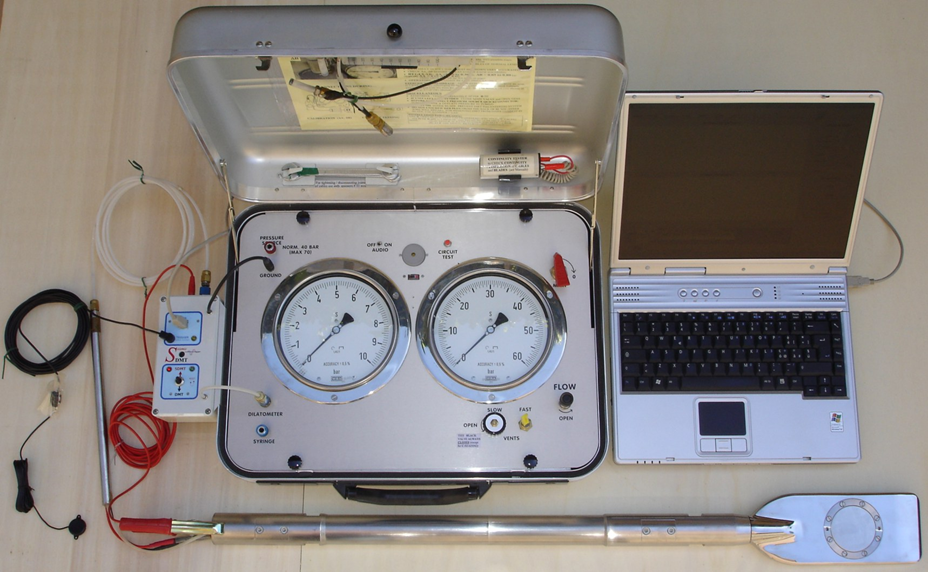

DMT use a 15mm thick, 96mm wide stainless steel blade with a 60mm diaphragm on one side of the blade. The blade is combined with a pneumatic system - electricity that transmits pressure through a nylon tube and an electric current flowing through it. The other end of the tube is attached to the controller. Nitrogen is used to apply pressure to the blade. The DMT blade unit is penetrated deep into the ground, the membrane is inflated to measure the expansion coefficient.

DMT has the results in a "pressure - displacement" relationship of the soil. Therefore, the application in estimating the deformation modulus, the horizontal load capacity of the pile, the stress state and the non-draining shear strength are of high reliability.

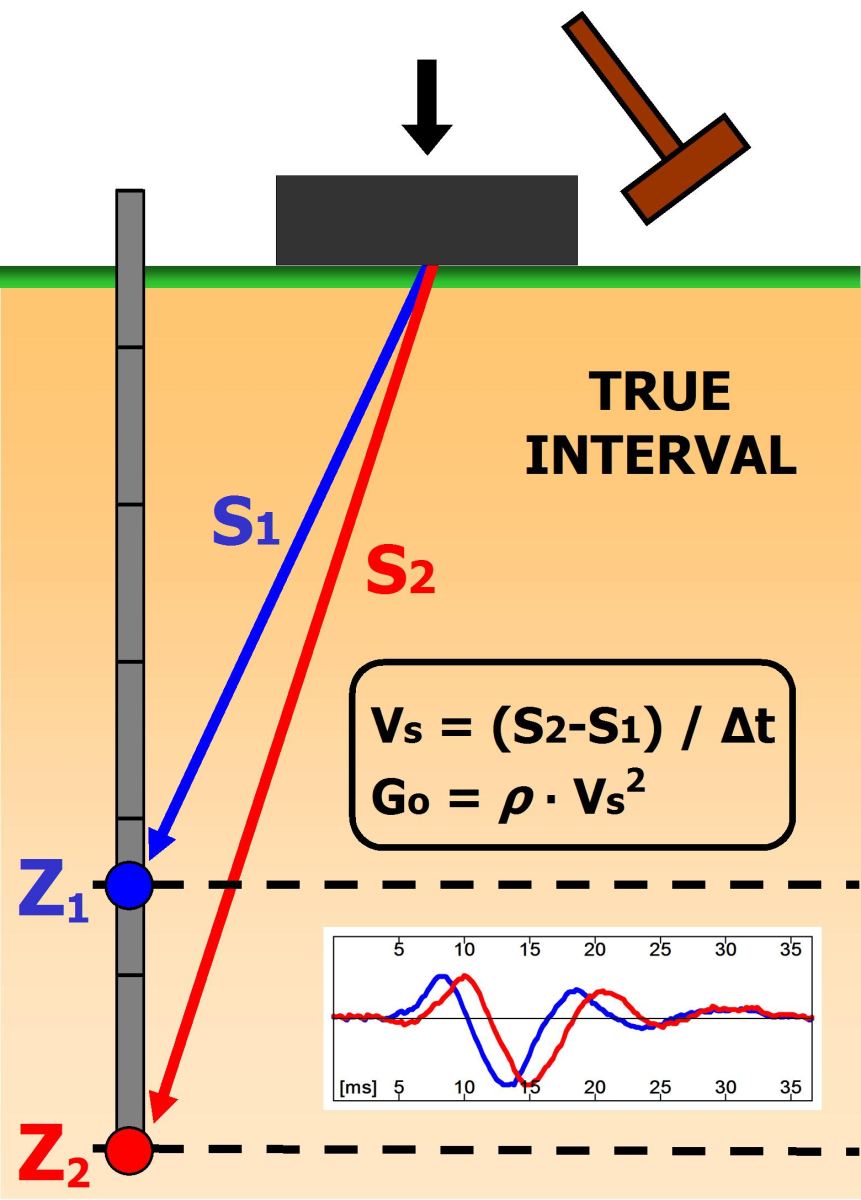

In addition, The supplier - Prof Marchetti also has a DMT combine with SMDT seismic measurement which is a combination of DMT and a Seimic module mounted on the top of DMT, so it called method SDMT. However, these are two independent tests that are performed at the same depth.

Standards: ASTM D6635 (2007), EUROCODE 7 Part2 (2007), ISSMGE –TC16 Report (2001).