Multinnov builds technical solutions with the latest technologies on the market. Multinnov is a specialist in robots for confined environments inspection with self-developed products including Stereo2 - indoor equipment for confined space inspections and ROView- Inspection Rover for pipelines and confined space inspections.

Multinov's designs and engineering office are constantly evolving so our products and services satisfy an increasingly greater and more sophisticated demand.

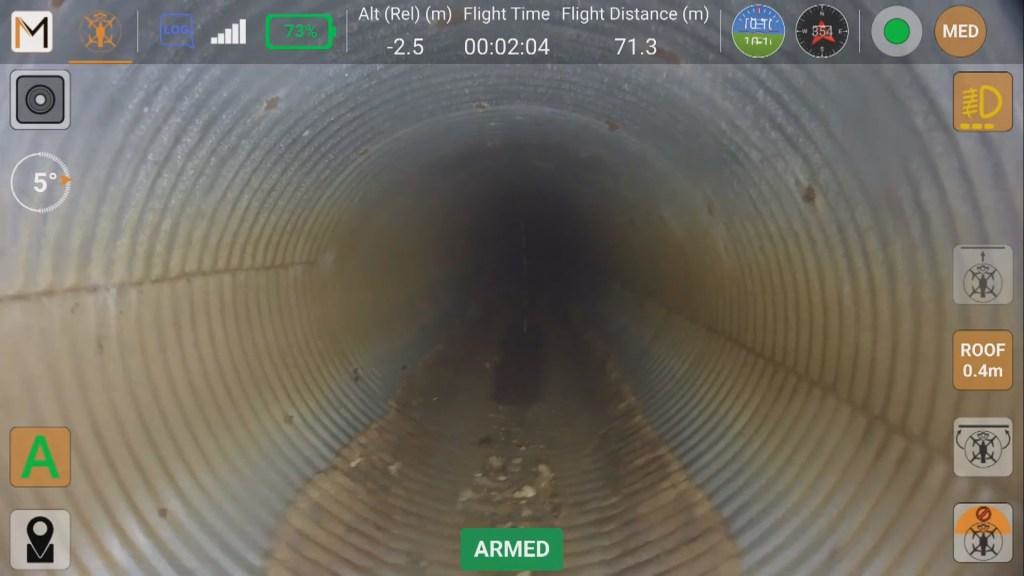

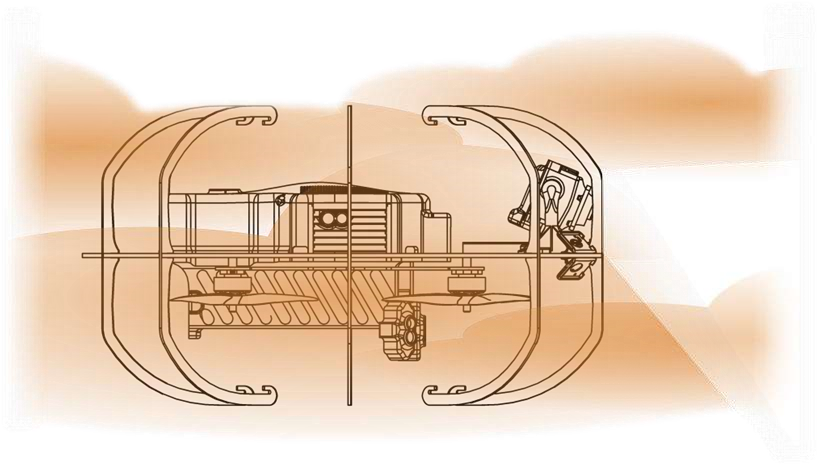

Application: Confined space inspections, the Stereo2, a kind of Indoor Inspection Equipment, designed for industrial environments such as nuclear, petrochemical, maritime, underground in geological formations, inside pipelines for remediation and sewer projects.

Move and navigate in the most difficult conditions without requiring a GPS signal to keep men away from danger.

Features:

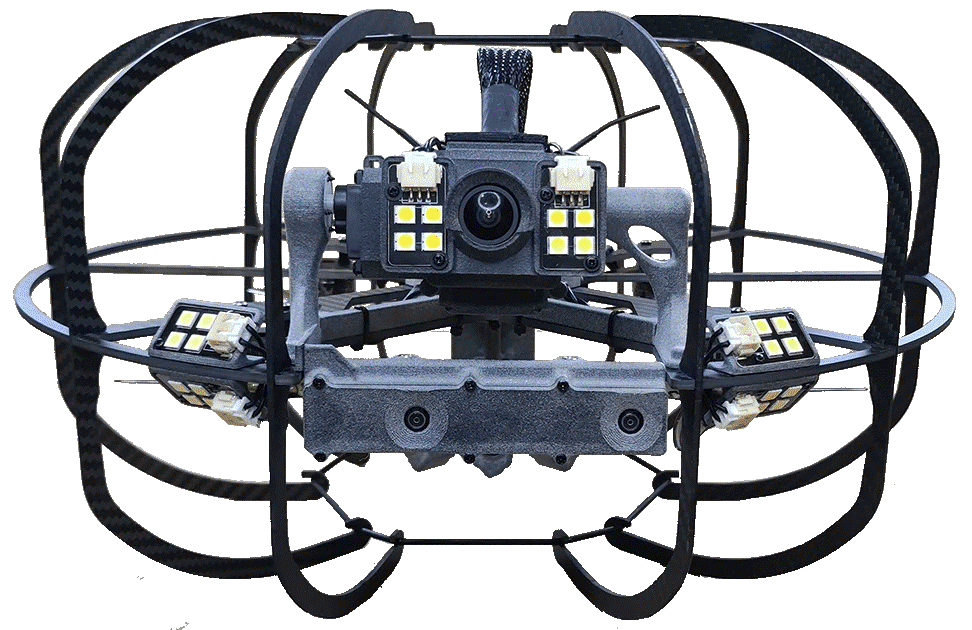

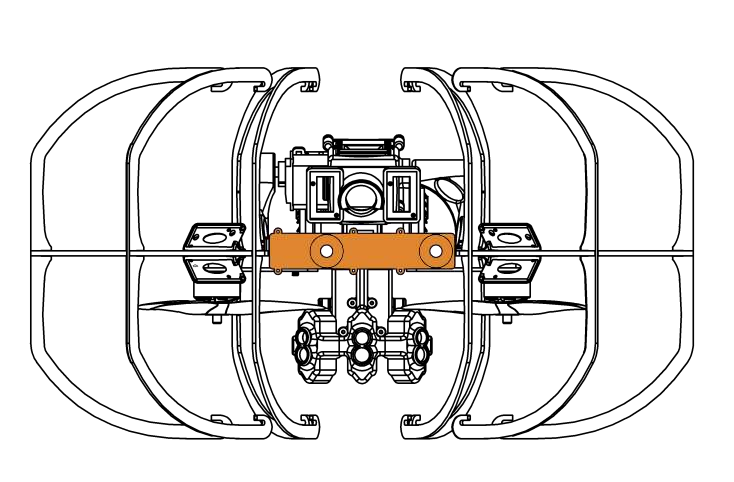

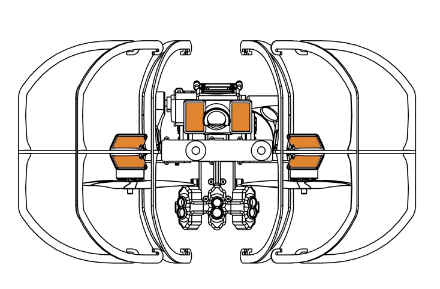

- Protective cage: Allows contact with the walls without risk to the machine. In a confined environment, trying to avoid any contact is unrealistic. It is therefore necessary to be able to bounce on the surfaces and continue the inspection.

|

|

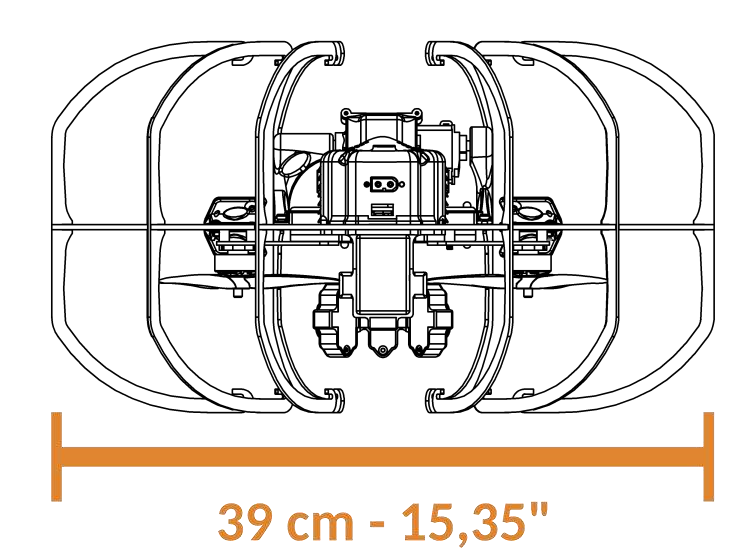

- Smaller size: A small diameter equipment is more nimble to move and fit in tight environments. Moreover, with a diameter of less than 40cm, the Stereo2 is able to cross most manholes.

|

|

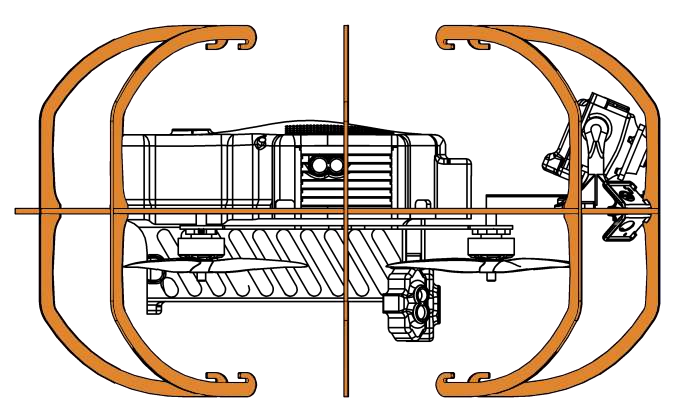

- Optical stabilization: Today, optical stabilization is the only way to overcome the lack of GPS signal in confined areas. The Stereo2 is also able to record its movements in real time for the pilot and to output them for 3D reconstruction.

|

|

- Illumination: Lack of light is a recurring problem in confined environments. Yet, it is essential for the cameras to be able to record the area. A Wide, uniform and powerful lighting is mandatory to operate effectively.

|

|

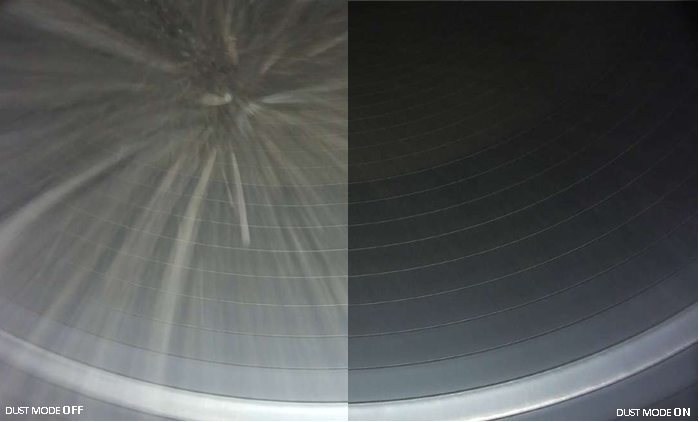

- Dust resistance: Present absolutely everywhere, it clogs up ventilation and causes the equipment to heat up. The Stereo2 has a passive ventilation system with wide openings that allows quick cleaning only with dry air. Once airborne, indirect lighting methods such as the Stereo2's dust mode are essential to ensure good visibility.

|

|

- HD video feedback: The better the definition of the equipment's video feedback, the better the pilot's ability to understand the hostile environments he is moving in.

|

|

|

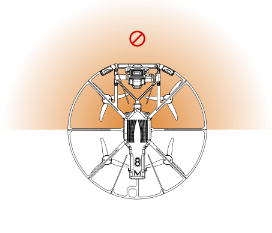

+ DISTANCE

Activates a protective bubble on the front of the machine. Protects the sensors by keeping a distance set by the operator. Useful to keep the equipment at a fixed distance from a wall to inspect it Eliminates the risk of touching the edges of a pipe.

|

|

|

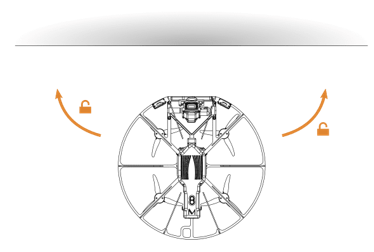

+ YAW-LOCK

Align the equipment at 90° angle from the surface to inspect. Works also on curved walls and therefore allows to inspect tanks without having to touch the yaw axis. The pilot remains in control of the yaw at all times, the equipment will take over as soon as the joystick returns.

|

|

|

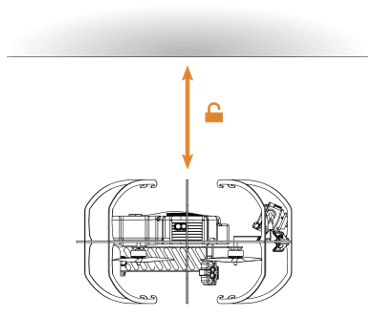

+ ROOF

Keeps the equipment at a set distance from any ceiling. Especially useful in pipes to let the equipment manage the tracking of the slope.

|

|

- Recording in 4k: The goal of any inspection is to get the best possible data set.

- 12 000 lumens leds: lighting system tailored for inspections in confined areas.

- Facing dust: The Stereo 2 has an indirect lighting mode to suppress the reflection of dust clouds for the camera.

- Photogrammetry: A 3D model gives you a new perspective on your inspection. Locating defects is easier than sorting through hundreds of pictures or watching a flight video. Using 3rd Software such as Agisoft Metashape or Pix4D for digital replicas from the videos taken by Stereo2.

|

Inspection

|

3D Reproduction

|

- Cage maintenance: Repairs to the cage can be made directly in the field in a matter of minutes and doesn’t require any tool.

- Control interface: A pilot interface as intuitive as possible for the pilot. Focus on technical inspection only from now on.