Construction at Tremont and Park Streets in November 1896.

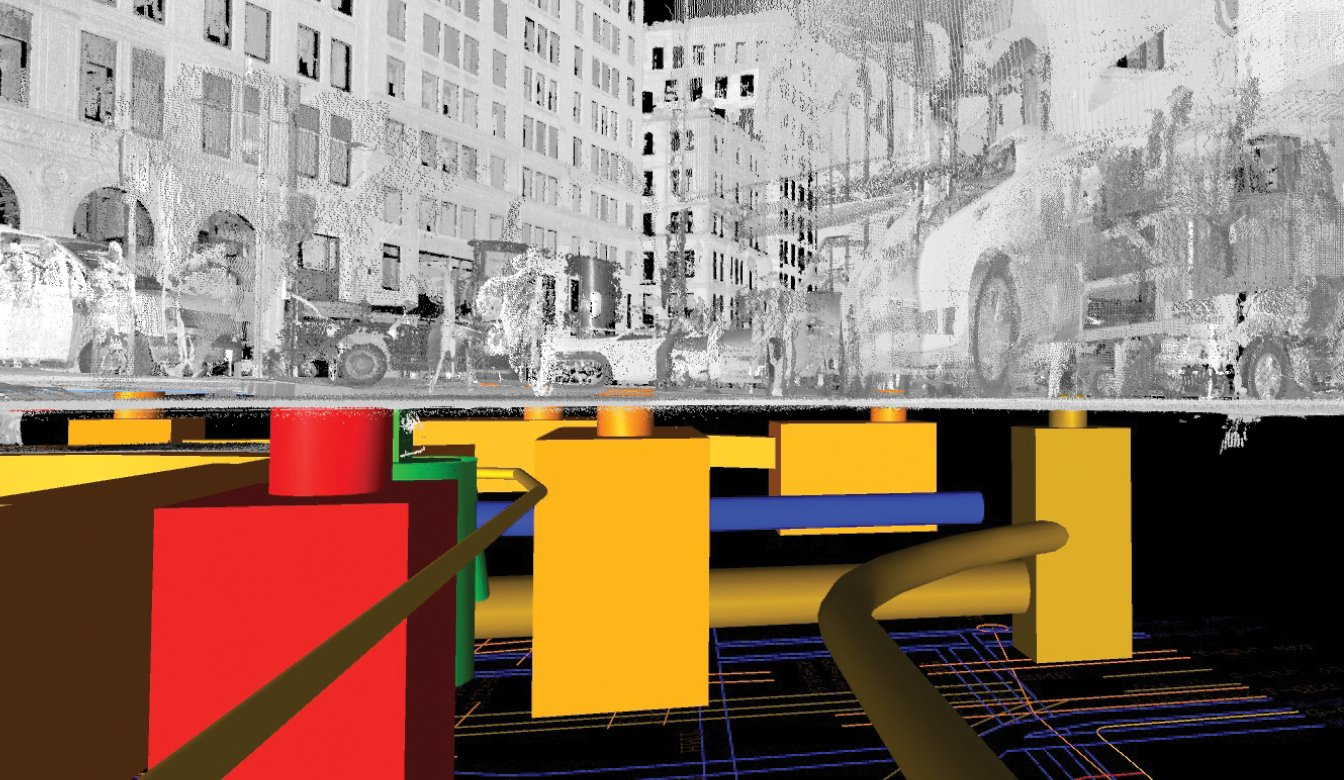

Ground Penetrating Radar (GPR), Electromagnetic Location (EML) and Building Information Modelling (BIM) are being extensively used to geolocate below the surface utility networks and hidden construction, reduce engineering risks and build a 3D map to aid surface and subsurface construction.

November 1896, Boston: Inspired by the subsurface tunnel constructions of the European countries, the industrial and trade cities of America, New York and Boston, tussled with each other to be the first in the race to move people under the busy streets. Boston won the race, and the city officials began the designing, planning and construction of ‘America’s first Subway’ at the Boylston station on the Tremont Street and Park Street under the Boston Commons in 1896.

Albeit the strategic engineering and construction plans, the construction of the Boston subway system came with its challenges — navigating and excavating subsurface buried utilities and ageing subsurface infrastructure. The unavailability of accurate subsurface infrastructure maps intensified the dangerous roadblocks engineers and surveyors faced in the construction process. One such roadblock occurred in the form of the infamous Tremont Street Gas Explosion, 1987, adjacent to the Boston Commons and the subway construction. The explosion created multiple debates with the common man protesting the planning and construction of any future subway station and the Boston’s Big Dig project. The need for digital mapping of existing and complex utility systems, gravesites, subsurface infrastructure — was, thus, established.

All construction projects require the geolocation of subsurface utility networks before and during the construction workflow. It is a crucial part of designing, planning, construction and maintenance of any project above the surface. Hidden subsurface utility networks have historically endangered the lives of many people. For construction owners and excavators, lack of information about the presence, nature and location of subsurface networks often creates a challenging situation.

Until two decades ago, there was no way of creating a 3D model of the infrastructure lying beneath our roads and pavements. In recent years, however, technology advancements have helped in subsurface utility engineering (SUE) for the intricate networks of underground cables, pipelines, tunnels, etc. to reduce inefficiencies and build a real-time 3D map of the subsurface. “It is important to look at the entire lifecycle of building infrastructure. Often when we look at the entire models, in very few cases you actually see the subsurface utilities mapped. In my interaction with the surveyors, especially the utility surveyors, actually that’s one of the biggest headaches or challenges out there – to combine the two worlds – surface and subsurface,” says Katherine Broder, President Construction Tools Division, Leica Geosystems

In the Architecture, Engineering and Construction (AEC) industry, conducting systematic surveys and digital mapping of subsurface utility infrastructure is of critical importance. “The subsurface is an incredibly complex environment which holds significant utility assets, infrastructure assets and buildings. With increasing pressure on space, higher land prices and a drive for compact, resource-efficient cities, we see more urban development underground. Knowledge of subsurface is, thus, key to delivering a successful construction and regeneration project,” explains Rollo Home, Lead Coordinator from Ordnance Survey for Project Iceberg.

In agreement is Michael Twohig, Director of Subsurface Utility Mapping, DGT Associates. “Accurate digital maps based on systematic surveys of underground infrastructure are critical for the numerous professionals in the AEC industry, asset owners, state and local government agencies and military organizations to help with all aspects of engineering, construction, operations and maintenance (O&M), so as to make informed decisions in their respective disciplines,” he says. The mapping and modeling of subsurface infrastructure helps construction companies by mitigating risk from a utility-congested scenario.

Typically, a pre-construction activity includes the process of SUE for geolocating the existing underground infrastructure and creating 3D models of the same using the BIM principles to initiate the construction process. Ignoring subsurface infrastructure, especially the utility networks, creates safety problems and can drag down the construction projects. “It is statistically proven that 90% of all construction projects are delayed and more than 50% of these delays are related to uncertainties in the subsurface. Accurate measurement, analysis and visualization of underground utilities using 3D models will significantly reduce this risk,” says Alexander van Noort, Global Business Line Director, Land Site Characterisation, Fugro.

Geoff Zeiss, Principal, Between the Poles, Canada, gives a good example of the importance of the SUE process for smart construction: “Not knowing where underground infrastructure is has engendered what is estimated to be a $10 billion per year industry in the United States. Every construction project requires locating underground utilities prior to and during construction.” For the most part of the construction projects, the subsurface is ignored, resulting in plateauing productivity. Geoff believes that project owners and contractors are increasingly recognizing the application of digital technology in subsurface mapping and construction: “People recognize the drag on construction projects and the broader national economy when digital technology is ignored in the subsurface. Improving the reliability of and sharing location information about the underground can be seen as a ‘low hanging fruit’ in the quest to improve construction productivity,” he says.

Understanding the technology

Construction projects (new and existing) require up-to-date technologies and improvement in the existing survey processes in geotechnical engineering. New technology innovations have enabled the mapping of infrastructure buried underground. As Broder puts it, “Construction people are typically not the experts on detection, and they are not all surveyors. So, the technology has to touch a community that has a very strong need to get of course reliable data, but they also need it in a usable format to take decisions.”

Innovative technology solutions such as advanced sensors, Ground Penetrating Radar (GPR), electromagnetic location, LiDAR and BIM are playing a critical role in creating information-based solutions for subsurface project contractors. “Today, the best practices and survey principals of mapping the underground infrastructure inspired by our forefathers’ commitment incorporate new technologies to improve data collection, data storage and dissemination of highly reliable 2D and 3D utility information,” says Twohig.

Lately, GPR has particularly gained the attention of the subsurface industry. A GPR creates a map or the image of the subsurface for engineers and constructors using high-frequency radio pulses to detect structures and objects underground. A non-destructive and a non-invasive process, GPR offers an accurate view of a construction site that other schematics cannot achieve. On the other hand, electromagnetic locators are used in ‘passive’ and ‘active’ modes to determine the position and depth of the buried utilities. Heath Pritchard, Head of Major Projects, Geospatial Commission, explains, “The type of technology used will depend on the need of the user, but advances in data collection tools such as GPR and EML have the potential to not only improve safety and efficiency at individual excavation sites but also improve the quality and usefulness of the dataset itself, should this data be used to correct inaccuracies and fill missing gaps.”

Echoing Pritchard’s views, Zeiss points out, “The technologies that are currently considered best practices for detecting underground utilities have been used for decades and are characterized as being slow, unreliable under certain conditions and for certain types of underground equipment, and hazardous for the operator. Lately, GPR has been getting significantly increased attention primarily because it can detect both metallic and non-metallic underground objects, capture continuous digital scans, and because it can capture the 3D position of underground objects.”

The contractors, surveyors and project owners are increasingly relying on advanced integrated hardware and software capabilities to map the subsurface infrastructure. While the hardware enables the detection of the infrastructure, it is the software which processes and presents the results in a 3D map. Noticeable advancements in both for subsurface mapping have increasingly improved the accuracy and the speed of the subsurface information that is shared with the project owner. The use of GPS, Bluetooth signals, Cloud and GIS are all found to be facilitating the pre-construction and subsurface construction process. “The hardware has become more user-friendly, more robust and now has nice touches such as being Bluetooth enabled, which allows seamless connectivity between devices on site. GPS enabled devices, on the other hand, help hugely in terms of global accuracy, while monitoring an employee on site. I believe that it’s in the software areas that the major advances have occurred. Software is becoming easier to use, more robust and is able to quantify repeat patterns, algorithms, etc.,” says John Robinson, Director, Malcom Hughes Land Surveyors Limited, United Kingdom. Thus, the current hardware and software improvements have dramatically improved the efficiencies and capabilities of the industry-standard tools.

Beyond GPR and EML, which are detection sensors, there are positioning sensors that are crucial because they gather data which is accurate and enables the correlation of the surface with the subsurface. Moreover, robotic total stations, GNSS and other technologies are also brought together to combine the two worlds. “The value proposition lies in the software,” adds Broder. Software is the platform that manages the data, brings the data together in a very accurate way to then offer it to the target groups.

In construction, the adoption of BIM is a major trend that has accelerated in the last decade, motivated by the need for sustainability and higher productivity. BIM is also found to be critical in reducing the engineering risks associated with the subsurface construction site. It makes it possible for the project owners to evaluate and assess in detail the impact of the new construction on the existing subsurface infrastructure and vice-versa. Applying the BIM principles in the geotechnical process is known to help reduce project risks and uncertainty, create better site investigation, generate a 3D geological model and streamline workflows to save time and effort.

A fully integrated, multi-disciplinary BIM software is used by construction companies to not only reduce the overall costs but also reduce inefficiencies in underground facility records and better visualize potential obstacles before and after construction. Robinson states that BIM is crucial for building a real-time 3D map of the subsurface. “It is vital that the above and below ground modelling is viewed as a single project to fully realize the advantages of BIM. Being able to see below the ground data in 3D and with the actual/perceived sizes/diameter of underground utilities helps engineers understand the risks presented in a visual way that enables easier clash detection.”

Integrated BIM and geospatial solutions work in unison, providing improvements in the subsurface infrastructure detection, project return on investment, and lifecycle management of a facility and helps mitigate the risks associated with underground activities. “BIM and geospatial provides the basic technology for modelling underground infrastructure,” says Zeiss. GIS and BIM solutions together provide the ability to observe and better understand the subsurface and complex utility networks to cross-reference it with the above surface modalities for future construction activities. BIM and GIS solutions – available for the subsurface utility engineers, together help generate detailed plans of the subsurface conduit and by using the visualization tools and clash detection capabilities, construction companies are able to resolve conflicts between the new and existing construction features.

Innovative digital solutions

There are numerous technologies that have augmented the findings of the subsurface infrastructure. 3D reality capture solutions, mobile laser scanners, LiDAR, drones and thermal imaging systems are gaining footing in the subsurface utility mapping for construction projects. “New sensing and sensor technologies are beginning to capture more data, more precisely about assets, their condition and the soil they sit in,” adds Rollo Home.

In June 2019, the UK government launched its Government Technology Innovation Strategy. This strategy sets out the foundation needed for the government to innovate through emerging technologies. It provides a framework for the departments to use technology as they make plans for digital data. Technology innovations are also expected in subsurface infrastructure mapping solutions. “Recent years have seen significant technical advances in the way we collect, store and analyze geospatial data. As technology and markets develop, it is likely that future software and hardware will emerge that are not known today,” Pritchard adds.

Twohig states that there are already many sophisticated investigative technologies that exist for subsurface investigations. He says, “Sophisticated geophysical investigation technologies have seen widespread adoption to assist with locating and mapping human-made features such as utilities, tunnels, vaults and underground tanks. Tools that were originally designed to map the subsurface geology have adapted to infrastructure mapping, coinciding with the growth in industry awareness and demands.” He further stresses on the specific advancements in the geospatial domain, saying that the use of drones and LiDAR has had a tremendous impact on subsurface infrastructure and in locating the results of our investigations.

A report by KPMG, Smart Infrastructure Mapping Underground Utilities, emphasizes on embracing the application of new technologies — advanced sensors, electronic sensors, robots, cameras and Machine Learning — to map the subsurface infrastructure. Zeiss highlights, “There are important technology innovations in subsurface infrastructure domain — reality capture for above and below ground and Machine Learning to detect and assess network assets that are poised to change the utility operating business dramatically.”

The use of Augmented Reality to see the subsurface utility infrastructure is a fascinating technology trend. vGIS, a tool in this field, harnesses the capabilities of the three technologies – Augmented Reality, GIS and the Microsoft Hololens – and allows for an immersive experience. The geospatial data is converted into Augmented Reality displays and holograms that enable the field workers to see the subsurface infrastructure to make informed decision to plan excavations for subsurface construction.

National policies and standards

Subsurface information is a national challenge which requires stakeholders to collaborate across all sectors. The role of the national government is, thus, critical. Recognizing the social, economic and environmental costs of maintaining a register of subsurface assets, the governments are encouraging the sharing of the location of subsurface infrastructure.

The Geospatial Commission, part of the UK government’s Cabinet office, is investing £3.9 million in two pilots (one led by Ordnance Survey in the North East of England, the other by the Greater London Authority in London) to test the feasibility of creating a national data sharing platform of the underground assets which aims to show the geolocation of the subsurface assets (including pipes, electricity and telecom cables, ). “For the Geospatial Commission’s national underground asset register pilot, this means making better use of the data already held by underground utility asset owners across the country and promoting new technologies and processes to fix inaccuracies or gaps in data. A data-sharing platform showing the location and condition of underground assets will lead to better planning of excavations and improve safety for workers,” stresses Pritchard.

In the Netherlands, a legislation was passed in 2015 by the States General to create the Basisregistratie Ondergrond (BRO) or the Key Registry for the Subsurface. The law mandates the excavators to share geotechnical data with the registry. While the role of the national government is to ensure that the data is maintained, the private geospatial companies are also involved in the BRO. “In many cases, the private geospatial companies gather, analyze and record the BRO data. In others, they use the BRO data in their primary process and develop and/or use the software that supports the primary processes in which the BRO data is used,” a government source said.

Project Iceberg – a joint initiative by the British Geological Survey, Ordnance Survey and the Future Cities Catapult aims to increase the viability of land through better use of subsurface information. As Home explains: “What is needed is a government-backed data-exchange framework for the subsurface that can be integrated with existing city data systems. Accompanying national standards and supporting legislation are also needed to ensure that data is collected and shared in the correct format.”

Importance of standards

When Geospatial Commission launched its Call for Evidence in 2018 – many of the respondents cited the challenge of connecting datasets and the role standards could play in improving interoperability. “The UK has hundreds, if not more, owners of underground utility assets with much of this data held in varied formats, scales and qualities. When data is described and recorded using common data standards and data transformation processes, the ease at which it can be used across systems and software increases. Common standards and data transformation processes also leads to workplace efficiencies by reducing the time and effort required by end-users to understand and use the data,” Pritchard explains.

Robinson, who is also the co-author of the PAS128: 2014 and a member of the Steering Group PAS256: 2017, highlights, “Without a standard or robust specification, the quality can’t be measured between practitioners or equipment. In the UK, PAS128 is the go-to specification. In the US its ASCE 38-02. Many other countries around the globe use these two specifications as they are regarded as the best. Every country will have its own unique needs, and often a specification will need updating/altering to accommodate.”

From a utility perspective, standards are of critical importance since spatial reference is involved. Noort adds, “At Fugro, we follow the PAS 128 which outlines the levels of accuracy required. Standards are extremely important — for example the spatial position of the utility is essential. If the coordinates were determined by hand-held GPS with an accuracy of between 1m to 5m, this could lead to significant problems in construction, maintenance or inspection.” A spatial reference to the subsurface assets is important, which needs to be defined according to the standards established and survey procedures and protocols.

The way forward: Technology, standards and resolve

Any construction or operations and maintenance project essentially requires an understanding of the subsurface infrastructure and the different classifications of the infrastructure. These range from soil structures, rock patterns, hydrology, man-made utilities, subsurface construction, cables and sewers. A construction project is fundamentally at huge risks associated with safety, cost and schedule if during the preconstruction phase there is incomplete and inaccurate subsurface information. It is to be noted if the subsurface infrastructure is not detected prior to construction, it can result in significant additional costs across the entire design, planning and construction workflow. One can also not ignore the potentially high risks to construction personnel and the existing infrastructure.

Every country in the world is facing similar background infrastructure problems — unreliable existing record data and subsurface utility congestion, among others. While the subsurface has attracted the attention of the survey equipment providers, the benefits of the new technology innovations need to be communicated and explored by the construction companies, project owners and surveying organizations.

The ease with which the construction companies can unravel the mysteries of the subsurface is imperative for the successful project delivery of a construction project. The AEC sector needs to give due attention to SUE’s to speed up their construction process while reducing its engineering risks, improving productivity and ensuring quality and safety. To sum it up, as the subsurface data becomes accessible and curable according to the given standards and through a subsurface platform— there will be better opportunities for the AEC sector to reduce unexpected challenges and accelerate construction projects of the future.

Source: https://www.geospatialworld.net/article/technologies-to-map-subsurface-infrastructure/