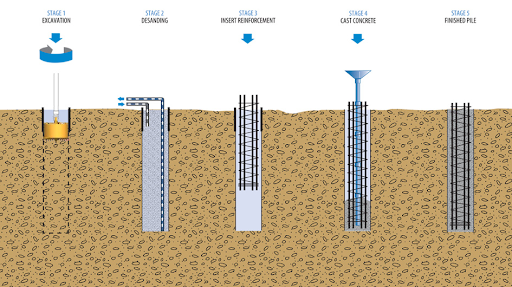

Several methods of construction exist today for the construction of drilled shafts (Reese and O’Neill 1999). The most widely used method today is the wet method, i.e., shafts are cast under wet conditions using bentonite slurry in order to keep the borehole open vertical during drilling to avoid collapsing of soil and preventing proper casting of the concrete. Several defects in form of necking /bulging may be occurred. These defects occur due to failure of soft vertical strata after excavation of soil /during lowering of cage (Sarhan et al. 2003) and these defects occupying up to 15% of the cast in situ pile section could remain undetected. Camp et al. (2007) recorded that, out of 441 piles tested on different projects in South Carolina, around more than 70% of the projects had at least one pile containing a defect. Such defects in the integrity of the cast in situ pile can affect their pile capacity and ability to transmit the design loads and hence quality control of pile construction is a major important critical factor.

Fig.1: Drilling Shafts Process.

Several methods are currently used to perform Non Destructive Testing (NDT) of deep foundations. Cross-hole Sonic Logging (CSL) is a common and most reliable technique among the most common methods of NDT testing. Complete guideline is available in ASTM D 6760 (2008). It is observed that defects near the top of a drilled shaft will significantly affect its structural capacity due to unsound concrete.

To better understand Cross-hole Sonic Logging method and process for implementing it, below are excerpts from the ASTM D6760 - 08: Standard Test Method for Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing.

Principle of the Cross-hole Sonic Logging:

The actual speed of sound wave propagation in concrete is dependent on the concrete material properties, geometry of the element and wavelength of the sound waves. When ultrasonic frequencies (for example, >20 000 Hz) are generated, Pressure (P) waves and Shear (S) waves travel through the concrete. Because S waves are relatively slow, they are of no further interest in this method. In good quality concrete the P-wave speed would typically range between 3600 to 4400 m/s. Poor quality concrete containing defects (for example, soil inclusion, gravel, water, drilling mud, bentonite, voids, contaminated concrete, or excessive segregation of the constituent particles) has a comparatively lower P-wave speed.

By measuring the transit time of an ultrasonic P-wave signal between an ultrasonic transmitter and receiver in two parallel water filled access ducts cast into the concrete during construction and spaced at a known distance apart, such anomalies may be detected.

Usually the transmitter and receiver are maintained at equal elevations as they are moved up or down the access ducts.

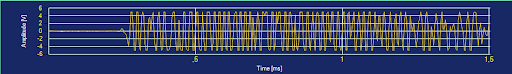

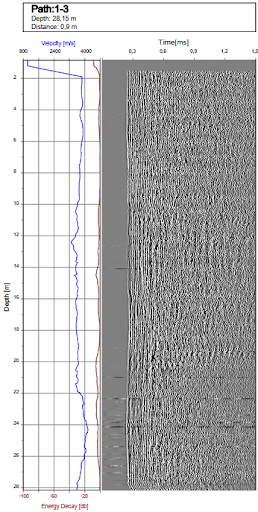

Two ultrasonic probes, one a transmitter and the other a receiver, are lowered and lifted usually in unison in their respective water-filled access ducts to test the full shaft length from top to bottom. The transmitter probe generates ultrasonic pulses at frequent and regular intervals during the probes’ controlled travel rate. The probe depth and receiver probe’s output (timed relative to the transmitter probe’s ultrasonic pulse generation) are recorded for each pulse. The receiver’s output signals are sampled and saved as amplitude versus time (see Fig. 2) for each sampled depth. These signals can be then nested to produce a “waterfall” diagram (see right side of Fig. 3).

Fig.2 Amplitude versus time.

Fig.3 Waterfall diagram.

Cross-hole Sonic Logging system including:

- 01 Control Units;

- 01 Transmitter Probe;

- 01 Receiver Probe;

- 02 Roller Cable;

- Acquisition Software.

Fig.4 Cross-hole Sonic Logging system.

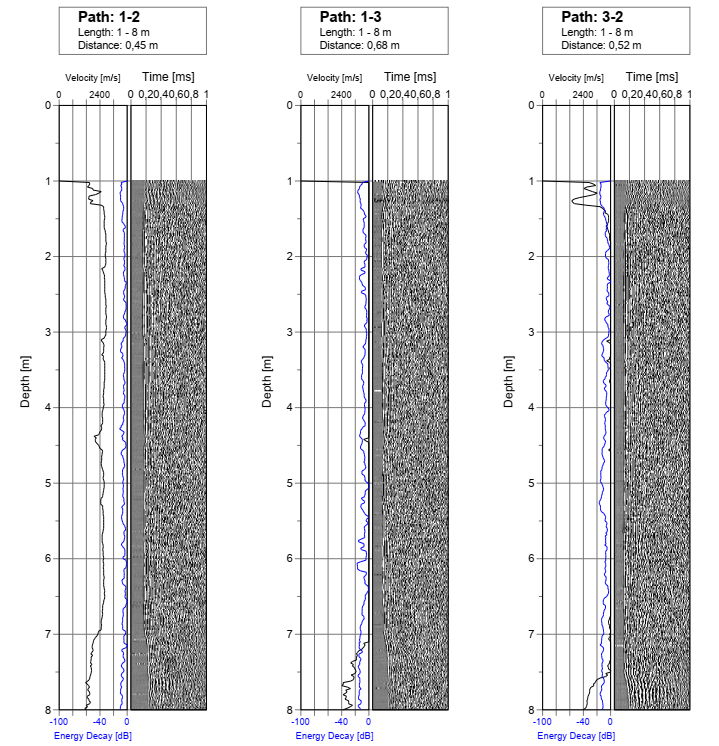

Data sample:

Fig 5: Data sample.

References: Bagui, S.K., Puri, S.K. & Subbiah, K. Cross hole sonic test results for analysis of pile load test. ABEN 1, 15 (2020).

https://doi.org/10.1186/s43251-020-00017-4

ASTM D6760 − 08: Standard Test Method for Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing

SOLGEO ALL-IN-ONE, Brochure: http://www.solgeo.it/media/strumento/SOLGEO_AllInOne.pdf