Introduction

Wire rope testing with magnetic flux leakage (MFL) is a well-developed non-destructive testing (NDT) technique for wire rope inspection. The measurement instrumentation is designed to detect local faults (LF) and loss of metallic area (LMA). Local faults are generally wire breaks while loss of metallic area is generally categorized as a gradual or extended loss in cross-sectional area due to corrosion, wear, or other wire rope deterioration mechanisms. This article introduces the reader to the MFL wire rope testing hardware and data.

Magnetic Flux Leakage Reference Documentation

There are a various important standards published by the American Society for Testing of Materials (ASTM), European Standards (DIN) and International Standard Organization (ISO) on the topic of wire rope inspection and rejection criteria. These include but are not limited to:

- ASTM E 1571: Standard Practice for Electromagnetic Examination of Ferromagnetic Steel Wire Rope

- DIN EN 12927-6: Safety requirements for cable way inspections designed to carry persons Part 6: Discard Criteria

- ISO 4309:2017 Cranes - Wire Ropes - Care And Maintenance, Inspection And Discard

These standards are applicable to a wide variety of machines ranging from mobile cranes, tower cranes, cantilever cranes, and cable ways for carrying people. These MFL testing standards lend themselves to many industries including: mining, transportation, maritime, amusement parks, and leisure industries.

In additional to ASTM, DIN and ISO standards there are a variety of regional codes that outline wire rope inspection requirements. For example, the New Jersey Administrative Code (NJAC) Chapter 14A Carnival – Amusement Rides outlines wire rope inspection frequency and discard criteria. In this regional code the wire rope discard criteria is fairly straight forward and is summarized below:

- In running ropes, six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay;

- In pendants or standing ropes, evidence of more than one broken wire in one rope lay;

- Any condition which causes the loss of more than one-third of the original diameter of the outside individual wires;

- Severe corrosion;

- Kinking, crushing, bird-caging, or other damage resulting in distortion of the rope structure.

The MFL wire rope testing discard criteria in in the ASTM, DIN, and ISO standards, however, is more complex. In DIN EN 12927-6: Safety requirements for cable way inspections designed to carry persons Part 6: Discard Criteria, for example, the discard criteria is broken down by loss of metallic area (LMA) and local faults (LF) separately.

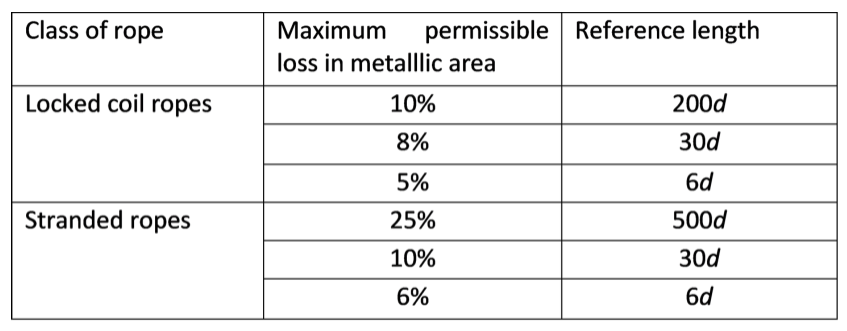

The LMA discard criteria depends on the class of rope – locked coil ropes or stranded ropes. The maximum permissible loss of metallic area is dependent on the reference length. For example, over a length of 500d, where d is diameter, the maximum LMA is 25%. The value decreases with reference length. The maximum allowable LMA of a reference length of 6d is only 6% during an MFL wire rope test.

Table 1: Maximum permissible loss in metalllic area

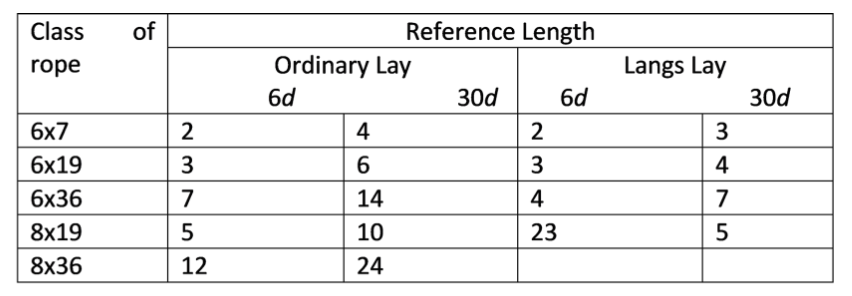

A similar approach is used for wire break discard criteria as shown in Table 2. For a Class 6x7 rope, only 2 wire breaks are allowable over a length of 6d. Over a length of 30d, 4 wire breaks are required.

Table 2: Maximum number of outer wire breaks

Magnetic Flux Leakage – Wire Rope Hardware

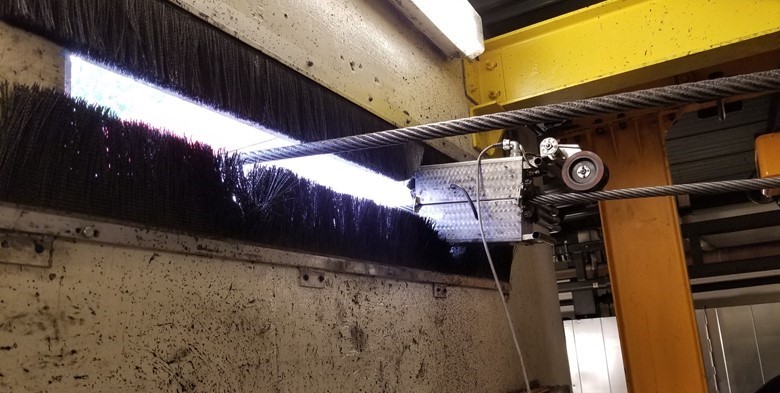

The measuring head is the most important wire rope testing hardware. In combination with the data logger and encoder wheel, the measuring head is mounted on the wire rope for testing as shown in Figure 1.

Depending on the manufacturer, cost, and vintage of the MFL technology the measuring head may be equipped with sensing coils and hall sensor for detection of LMA and LF, respectively. The LMA sensor quantitatively measures loss of metallic cross-sectional area caused by external or internal corrosion and wear. The axial MFL in the rope is directly proportional to the cross-sectional area when the wire rope is saturated magnetically.

The Localized-Flaw (LF) sensor qualitatively detects a wide range of external and internal wire rope defects such as wire breaks and localized corrosion pitting. The defects in the wire rope are essentially discontinuities that cause the magnetic flux to leak in the radial direction. The MFL leakage is then detected by the dedicated sensor.

The magnetic flux leakage measuring head is equipped with an encoder wheel that tracks direction and position.

One of the first steps in magnetic flux leakage testing of wire rope is equipment calibration and establishment of sensitivity to known changed in rope cross-sectional area. In this step, the objective is to correlate the magnitude of magnetic flux leakage to change in wire rope cross-sectional area change. One method to accomplish this is by running a calibration rod with at least two different diameters through the measuring head while the wire rope is centered in the head. The sensing device converts the MFL due to the CSA change to a voltage that is digitized and displayed on the data acquisition system.

The calibration process and data are shown in the video below. Three channels are displayed in the MFL rope test data. The top channel, with the green line data, is the channel dedicated to outer diameter wire breaks. The middle channel or red data, is the channel dedicated to inner diameter wire breaks. The bottom channel with the blue line data is the LMA channel. The first fluctuation in data occurs when the larger diameter calibration rod is inserted into the measuring head. In this case, the maximum amplitude response is approximately 80 mV based on the 50 mV/div scale. The second fluctuation in data at approximately 10 seconds into the test is the smaller diameter calibration rod which produced a maximum amplitude response 40 mV. The LMA channel detects the larger diameter calibration rod but barely registers the smaller diameter rod. In this case, the LMA channel sensitivity would have to be increased.

Source: https://www.techknowserv.com/post/wire-rope-testing-an-introduction-to-magnetic-flux-leakage-testing